In the fields of analytics, liquid handling and automation, it is necessary to monitor or control certain physical quantities. Suitable sensors are used to ensure plant safety, process control and secure results without any falsification. If this is not possible, individual components need to be checked separately at regular intervals for required system specifications.

Overview

The flow rate determines whether the correct quantity has been transferred in the desired time unit. Depending on the process and requirements, the flow rate can be determined inline or at the fluidic path end.

If a process requires an absolute quantity, the dosing accuracy of the system should be checked. This is mostly done gravimetrically.

Checking the liquid level prevents the primary tubes from running completely dry and the target tubes from overflowing. Common types of level measurement include conductivity measurement, capacitive measurement, optical measurement or ultrasonic measurement.

Monitoring is used for more security. Therefore, a warning or an emergency shutdown can be initiated.

Testing for leakage is useful when dangerous substances (highly flammable, explosive or toxic) are transferred. Depending on the concentration in the room air, it can lead a warning or an emergency shutdown during monitoring.

Air bubbles in completely filled fluidic systems can be a sign of leakage or outgassing of the medium. In both cases it is causing problems. For this purpose, ultrasound or thermal conductivity can be used as non-contact measuring methods.

Applications

Sampling system for retention samples

System for the collection of 24-hour retention samples from a production line.

The sample collection bottles and also the waste bottles are monitored by 2-level-sensors. One sensor checks if the bottle is mounted, the second sensor detects if the maximum fill level is reached.

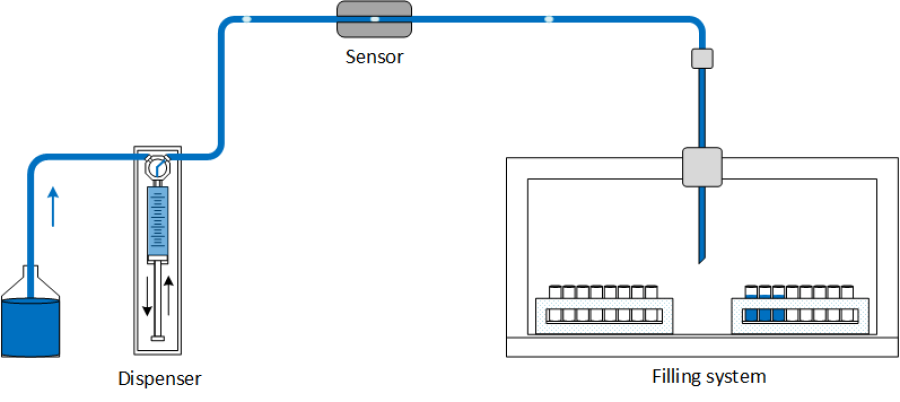

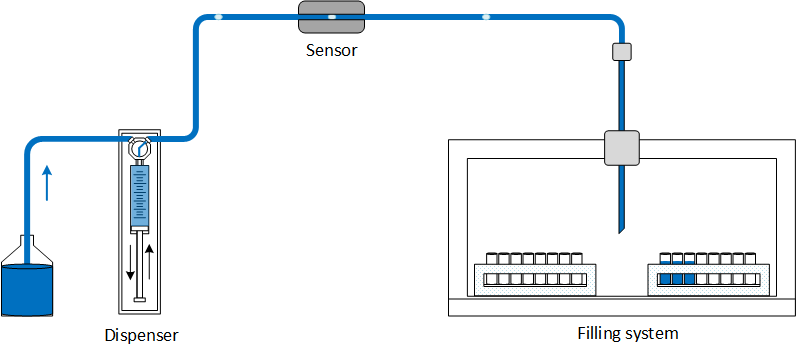

Eppendorf Caps filling system

High-precision filling system for Eppendorf Caps. During filling, a maximum tolerance of 0.2% is permitted. Smallest air bubbles can cause an error. Using in-process control with an ultrasonic detector, these bubbles can be detected and the bubble size determined. If a certain level is exceeded, the defective cap is marked.