d.Drive PUMP

The d.Drive PUMP is a compact and very precise pump for flow rates from nl/min to ml/min.

Low pulsation pumping & metering

The d.Drive PUMP is a high-precision, low-pulsation dosing pump for laboratory, process engineering and industrial applications for dosing from nl/min to ml/min. Due to the used materials, a variety of different media (aqueous, organic, aggressive, highly viscous, gaseous) can be transferred metal-free. The application field of d.Drive PUMP covers from chemistry, pharmaceuticals, biotechnology, medical technology, food industry up to manufacturing industries.

The pump can be controlled via a touch display, computer-based via RS323 or by PLC via an I/O interface.

Operating principle

The pump consists of two individual syringe drives. While one syringe delivers the liquid, the other syringe is preparing for the subsequent stroke. The alternation of both syringe motions is performed by two contrary acceleration gradients in order to achieve a smooth transition. The flow is almost pulsation free. The valves are positively controlled and the pump is self-priming.

The flow rates cover – depending on assembled syringe - a range from 0.04μl/min to 300ml/min. Besides continuous flow also finite dosing is realizable. Control and monitoring of the pump can be ensured by RS232, Bluetooth as well as by analogue or TLL-signals.

Additional to the pump mode every syringe drive can be controlled separately which enables various applications of liquid handling in research, development, production and process engineering.

d.Drive PUMP Product Video

Learn more about functionality and applications.

Operating

Touchdisplay

All functions can be controlled via the touch panel on the front. It enables simple, intuitive and direct operation of the pump. Relevant parameters can be easily configured and monitored.

Windows Software

The windows software enables the same control like the touch panel. Additional function: selection of units for flow rate, dose volume and dosing time.

RS232 Protocol

Technically versed users can control the pump directly using the RS232 command protocol and without special software.

I/O Interface

It is possible to control the pump using the I / O port via a process control system.

d.Drive PUMP - 2 Versions

for a wide range of applications

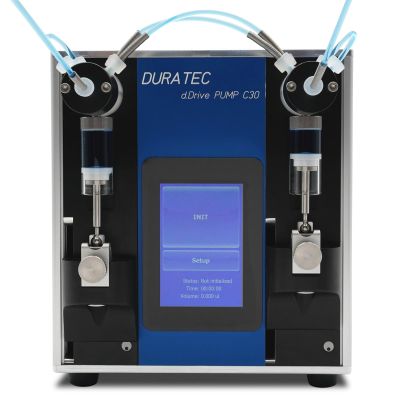

d.Drive PUMP C30

|

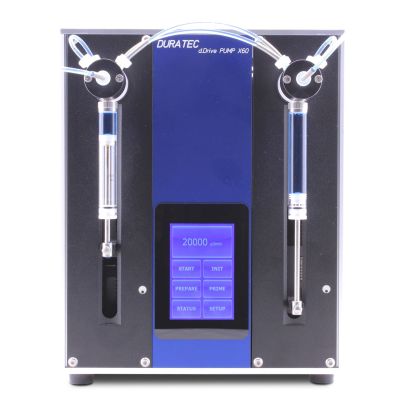

d.Drive PUMP X60

|

|

| Dosing modul |

Centris | XLP6000 |

| Part no. |

900763 | 900762 |

| Delivery includes | Pump, 2 Valves, Power supply (without syringes, tubing, software) | |

| Dispensing range | 0,042 µl/min - 75 ml/min | 0,4 µl/min - 300 ml/min |

| Pumping modes | continuous, finite, reversed | |

| Pressure range | 0 - 6 bar (depending on syringe size) | |

| Syringe volume |

25 µl - 12,5 ml | 50 µl - 50 ml |

| Time for full stroke |

6s - 3000 min | 6s - 160 min |

| Fluid path |

Borosilicate glass, PTFE, PCTFE, FEP, PEEK | |

| Control | Touch panel; serial via RS232; I/O port for TTL signals | |

| Power supply | 24 V / DC | |

| Dimensions | W: 185 mm / H: 204 (220) mm / D: 130 (180) mm | W: 220 mm / H: 275 mm / D: 160 (215) |

| Weight | 3,9 kg | 6,5 kg |

Accessories & Consumables

for d.Drive PUMP C30 / X60

FAQ

The flow rates and pressure range depends on the syringe size.

| Syringe | d.Drive PUMP C30 | d. Drive PUMP X60*1 | ||||

|---|---|---|---|---|---|---|

| Flow rate [µl/min] | Pressure[bar] | Flow arte [µl/min] | Pressure[bar] | |||

| max | min | max | max | min | max | |

| 25 µl | 150 | 0,042 | 6,0 | # | # | # |

| 50 µl | 300 | 0,083 | 6,0 | 300 | 0,313 | 6,0 |

| 100 µl | 600 | 0,166 | 6,0 | 600 | 0,625 | 6,0 |

| 250 µl | 1.500 | 0,414 | 6,0 | 1.500 | 1,563 | 6,0 |

| 500 µl | 3.000 | 0,827 | 6,0 | 3.000 | 3,125 | 6,0 |

| 1 ml | 6.000 | 1,653 | 6,0 | 6.000 | 6,250 | 6,0 |

| 2,5 ml | 15.000 | 4,133 | 6,0 | 15.000 | 15,625 | 6,0 |

| 5 ml | 30.000 | 8,265 | 4,1 | 30.000 | 31,250 | 6,0 |

| 10 ml | # | # | # | 60.000 | 62,500 | 4,1 |

| 12,5 ml | 75.000 | 20,663 | 1,6 | # | # | # |

| 25 ml | # | # | # | 150.000 | 156,250 | 1,6 |

| 50 ml | # | # | # | 300.000 | 312,500 | 0,8 |

* Data still under reservation of correctness

The pump is suitable for a wide range of different media (aqueous, organic, aggressive, highly viscous, gaseous), the wetted parts are made of borosilicate glass, PTFE, PCTFE and PEEK in the standard version.

If the fluid contains abrasive particles, this can cause increased abrasion in valves and syringes or clogging. If possible, use only particle-free media.